State Of The Art Facilities in India

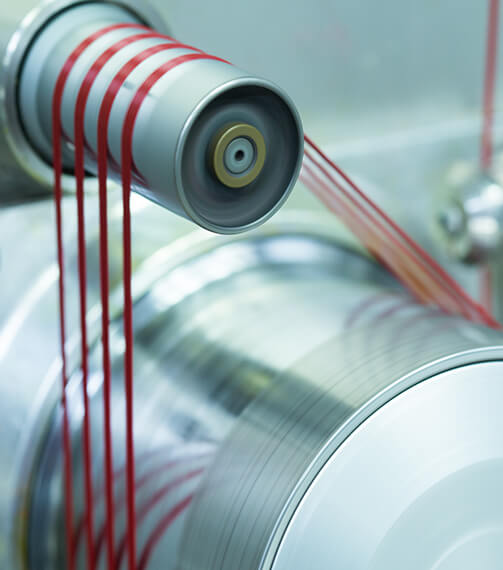

A leading specialty synthetic yarn manufacturer with world-class manufacturing technology for multipolymer products.

Largest Indian manufacturer of Bulk Continuous Filament yarns & one of the largest yarn dyeing house in Asia. We are committed to eco-friendly practices & products which ensure our promise towards sustainability.

Widest colour range of conventional dyed yarn

15k+

shades

Widest colour range dope dyed yarn

5k+

shades

Quality Control Center

Stringent quality checks on globally-benchmarked lab testing equipment such as Statimat ME+, Kibby G5.300, Mtuft, Hexapod, Tumbler Carpet Tester, Uster Tensorapid & Tester 3, UTR4C, Dynafil Me+, Texturemate Me+, X Rite Colour.

Research & Development Center

Government of India recognised, world-class R&D centre that pilots developments in spinning, knitting, texturising, tufting, weaving, printing and dyeing, with a masterbatch facility and 5000+ shade bank.